CHLOR ALKALI PLANTS

We provide solutions for chlorine and caustic soda industry to ensure greater competitiveness to our customers, through better performances in term of energy savings, investment costs, product quality and environmental impact.

We offer state-of-the-art products that feature engineering of the highest quality while taking economic, ecological and safety considerations into account.

The heart of Chlor-Alkali process is the electrolysis of NaCl brine (sodium chloride) or KCl brine (potassium chloride) to produce chlorine (Cl2), caustic soda (NaOH, sodium hydroxide) or caustic potash (KOH, potassium hydroxide) and hydrogen (H2), which are commodity chemicals required by industry.

As the market evolves, the demand for small-capacity chlorine plants is growing: liquid chlorine transportation is becoming more difficult and expensive; chlorine and caustic are the building blocks for industries in remote areas; and securing sustainable supplies of chlorine and caustic is becoming a key objective for chemical companies.

Small chlorine plants that produce sodium hypochlorite and other commodity chemicals downstream of the chlorine/caustic generation process are an attractive alternative to making bleach from chlorine and caustic purchased on the open market. These chlor-alkali plants, which use salt and electricity to make chlorine, caustic soda, and hydrogen on-site, can be used primarily to produce sodium hypochlorite, ferric chloride, calcium hypochlorite, hydrochloric acid, and other chlorine derivatives. It can also be used to produce feedstocks for a variety of other chemicals.

We offer Lump sum turnkey solutions and engineering & technology services for integrated management and development of chlor alkali plants. As a single point responsibility company for turnkey projects, we provide best in class caustic soda plant design, engineering, technology, procurement, construction and commissioning services.

Our caustic chlorine plants incorporate three major areas; brine preparation and purification plant, electrolysis and product handling & storage. Typical by products of chlor alkali and derivatives plant include caustic soda lye, caustic soda flakes, chlorine, calcium chloride, sodium hypochlorite, hydrogen peroxide, hydrochloric acid, stable bleaching powder and chlorinated paraffin wax (CPW).

Applications and Uses:

CAUSTIC SODA LYE & FLAKES

It is also known as Sodium hydroxide. It is used in production of pulp and paper, soaps, detergents, viscose fibre, zeolites, food additives, textile processing, organic chemicals such as dyes, inorganic chemicals such as sulphites, phosphites and aluminium refineries.

CHLORINE

It is widely used to treat water as well as in the manufacture of the following products:

Sodium hypochlorite, Calcium hypochlorite, Poly vinyl chloride (PVC), lsocyanates, Polycarbonate, Chloromethanes, Perchloroethane, Phosgene, Ferric chloride, Epichlorohydrin, Poly aluminium chloride, Silicon dioxide (aerosol) and Chlorinated paraffin.

HYDROCHLORIC ACID

Also known as hydrogen chloride or muriatic acid, it has a variety of applications.

Food grade hydrochloric acid is used in the production of food ingredients, food additives, and in the sugar and brewery industries. Industrial grade is used for other purposes, like petroleum refining and leather treatment.

SODIUM HYPOCHLORITE

Also known as chlorine bleach it works as a great steriliser, decolouring agent, oxidiser, germicide, fungicide, and deodorant. It is used as: A bleaching agent for rayon pulp, paper, cotton, linen and jute, a household bleach for fly control, water treatment, and pool chlorination, a disinfectant and deodorant in dairies.

DISINFECTION

These are anti-microbial formulations that are used to destroy micro-organisms in potable water, effluent and other surfaces. It kills molds, germs and bacteria by reacting with microbial cells to irreversibly denature and destroy many pathogens.

HYGIENE & CLARIFICATION

Swimming pool water generally contains many tiny particles in the form of impurities. the disinfection and removal of these impurities by bringing it out in the form of floe is much faster compared to conventional techniques. This floe can later be trapped in a filter.

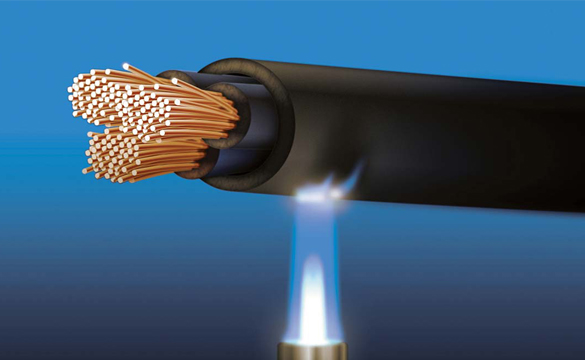

FLAME RETARDANT & PLASTICIZER

Chlorinated Paraffins used for wires & cables have good compatibility with PVC, which helps to get desirable results like Hardness, Tensile strength, Elongation, Ageing properties and Cell resistance.

DRILLING MUD ADDITIVE

Calcium Chloride is extensively used in oil and gas industry as an additive for drilling mud to cool and lubricate the drilling bit. It also helps in improving density of the mud to overcome formation pressures and keep oil, gas, and water in place.

PAPER SOLUTIONS

Bleaching - To produce high quality paper a pulp is required which does not discolour during storage or turn yellow when exposed to sunlight, and which retains its strength. Bleaching with Stable Bleaching powder achieves all three requirements and has the additional advantage of improving absorption capacity.

OIL AND GAS

Drilling fluids for borehole stability

TEXTILE

Dyeing process and as a desiccant for moisture control.

PHARMACEUTICALS

Chlor-alkali chemistry plays an important role in the development of modern medicines. Around 88% of advanced drugs depend on chlor-alkali chemistry for portion of their generation prepare. These incorporate drugs for asthma, diabetes, sadness, tall blood weight, tall cholesterol and indeed cancer.

These drugs only use chlor-alkali in their synthesis :

- Hydrochloric acid : Control the pH during the production process,

- Chlorinated solvents : To separate and purify the active ingredients,

- Sodium stearate : To enhance the effectiveness of ingredients in creams and ointments

- Chlorine : To purify borosilicate glass tubes that are used to safely store and transport vaccines.